Scope T&M Heat Exchangers

Shell & Tube

Scope MFG is a leading EPC contractor designing and building the optimum solutions in shell and tube heat exchangers making use of the smallest footprint to achieve the required output.

Plate & Frame

ScopePX plate and frame heat exchangers consist of a specific number/application of specially corrugated metal plates assembled in a frame and bolted between two pressure plates, one fixed and one adjustable.

ScopePX plate and frame heat exchangers are normally supplied with stainless steel plates. Titanium plates and other materials are available as an option.

ScopePX plate designs have been optimized for Media-to-Media heat transfer to provide enhanced performance in various applications.

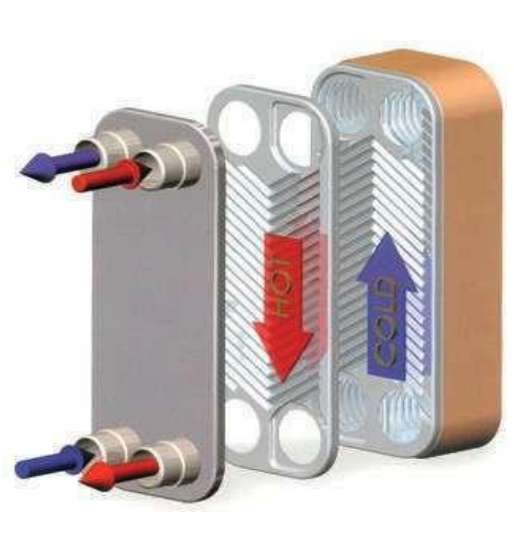

Brazed Plate

Scope offers brazed plate heat exchangers for refrigeration, hydronic heating, and process temperature control applications. The heat exchanger plates and connections are made from 316 stainless steel or different options as per requirements, to provide improved corrosion resistance. Standard designs include copper brazed plates. Nickel brazing is available as an option.

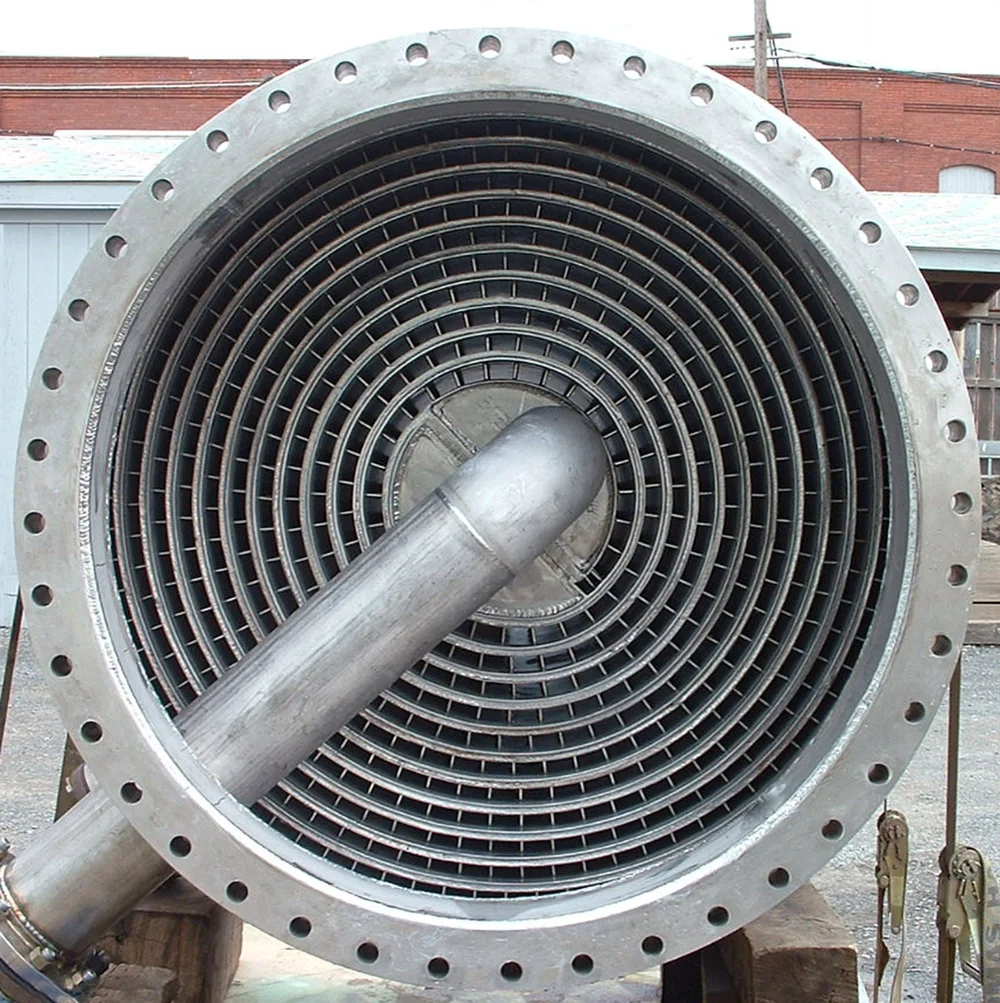

Spiral Heat Exchangers

Scope offers brazed plate heat exchangers for refrigeration, hydronic heating, and process temperature control applications. The heat exchanger plates and connections are made from 316 stainless steel, to provide improved corrosion resistance. Standard designs include copper brazed plates. Nickel brazing is available as an option.

ScopeX is a compact exhaust gas heat exchanger especially designed for waste heat recovery from gas turbines as well as from Diesel engines Either dirty or clean process flue gas. It could also be used as an economizer/ condensing economizer e.g. for gas or diesel fired boilers. Models available up to 10MW thermal. Higher output could be built as per application.

The heating surface of ScopeX has been developed for easy maintenance. Cleaning can be performed either with a pyrolysis process when operating in dry-run mode or using optional soot blower ports or network with compressed air, steam or water.

Applications: ScopeX can operate with a diversity of media, including water, steam, triethylene glycol (TEG) and thermal fluid oil (TFO).

Pressure vessels

Scope MFG offers pressure vessel design and fabrication which are used in power generation, petrochemical, fertilizers and refinery projects utilizing carbon steel, stainless steel and various exotic alloys. We can manufacture from an existing drawing or design & manufacture for your unique project

specifications from scratch.

Whether your application requires a process vessel, expansion vessel, ATM drain tank, deaerator, knock out drum, expansion tank, air receiver and separators we can help!