In the realm of power generation from waste heat recovery, geothermal sources, microgrids, combined heat and power (CHP) systems, and oil and gas applications, the efficiency of the Organic Rankine Cycle (O.R.C.) plays a pivotal role. Understanding the impact of temperature differentials on the cooling cycle and overall efficiency of an O.R.C. unit is essential for optimizing performance and maximizing energy output. This article delves deep into the intricate relationship between ambient temperatures and O.R.C. efficiency, exploring the various influences on output and strategies to mitigate negative impacts while enhancing positive outcomes.

The Significance of Ambient Temperature Differentials

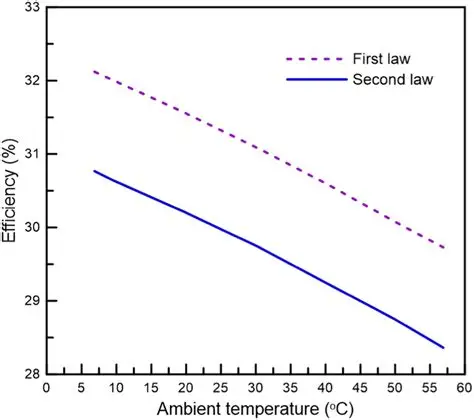

The efficiency of an O.R.C. system is intricately linked to the temperature differentials experienced during its operation. Ambient temperatures directly affect the heat exchange processes within the system, influencing the conversion of heat into usable energy. As temperatures fluctuate, the performance of the O.R.C. unit can vary significantly, impacting both the power output and the overall effectiveness of the cycle.

Impact on Output and Efficiency

1. Output Variations:

Ambient temperature differentials can lead to fluctuations in the power output of an O.R.C. system. Higher temperature differentials generally result in increased efficiency and greater energy production. Conversely, lower differentials can lead to decreased output and reduced overall performance. Understanding these variations is crucial for predicting and optimizing system performance.

2. Efficiency Factors:

The efficiency of an O.R.C. cycle is influenced by several factors related to ambient temperatures:

- Heat Transfer Rates: Higher temperature differentials typically enhance heat transfer rates, improving the efficiency of the cycle.

- Fluid Properties: The choice of working fluid in the O.R.C. system can impact its efficiency at different temperature differentials.

- System Design: The design of the heat exchangers, turbines, and condensers must be optimized to operate effectively across varying ambient temperatures.

Minimizing Negative Impacts and Amplifying Positive Effects

To mitigate the negative impacts of temperature differentials and amplify the positive effects on O.R.C. efficiency, several strategies can be employed:

1. Thermal Storage Systems:

Integrating thermal storage systems can help buffer temperature fluctuations, ensuring more stable operating conditions for the O.R.C. unit. By storing excess heat during peak periods and releasing it when ambient temperatures drop, thermal storage can optimize system performance.

2. Advanced Heat Exchanger Designs:

Utilizing advanced heat exchanger designs that are capable of adapting to changing temperature differentials can enhance heat transfer efficiency and overall cycle performance. Plate heat exchangers, finned tubes, and microchannel heat exchangers are examples of innovative designs that improve heat exchange processes.

3. Optimal Working Fluid Selection:

Choosing the right working fluid for the O.R.C. system based on the temperature differentials encountered is crucial. Different fluids have varying thermodynamic properties that can impact the cycle efficiency at different temperature ranges. Conducting thorough fluid analysis and selection is vital for maximizing system performance.

Conclusion

In conclusion, the impact of temperature differentials on O.R.C. efficiency is a critical consideration for engineers, technical professionals, and procurement audiences involved in power generation applications. By understanding the nuances of how ambient temperatures influence the cooling cycle and energy output of an O.R.C. unit, stakeholders can implement tailored strategies to minimize negative impacts and amplify positive effects. Through advanced thermal management, optimal fluid selection, and innovative heat exchanger designs, the efficiency of O.R.C. systems can be optimized across varying environmental conditions, ensuring sustainable and reliable energy generation.

This article serves as a comprehensive exploration of the interplay between ambient temperatures and O.R.C. efficiency, empowering readers to delve deeper into the intricacies of temperature differentials and their implications on power generation systems. In the next segment of this series, we will delve into the crucial aspect of heat source selection in O.R.C. systems, further expanding on the optimization strategies for enhancing performance in diverse operating environments.