As we delve into the intricacies of Organic Rankine Cycle (O.R.C.) systems, it is essential to understand the profound impact of ambient temperatures on the cooling cycle and overall efficiency of these units. In this article, we will explore the various effects of ambient temperatures on O.R.C. performance, discuss the consequences on output, and provide insights on mitigating the negative impacts and amplifying the positive ones.

Understanding the O.R.C. Cooling Cycle

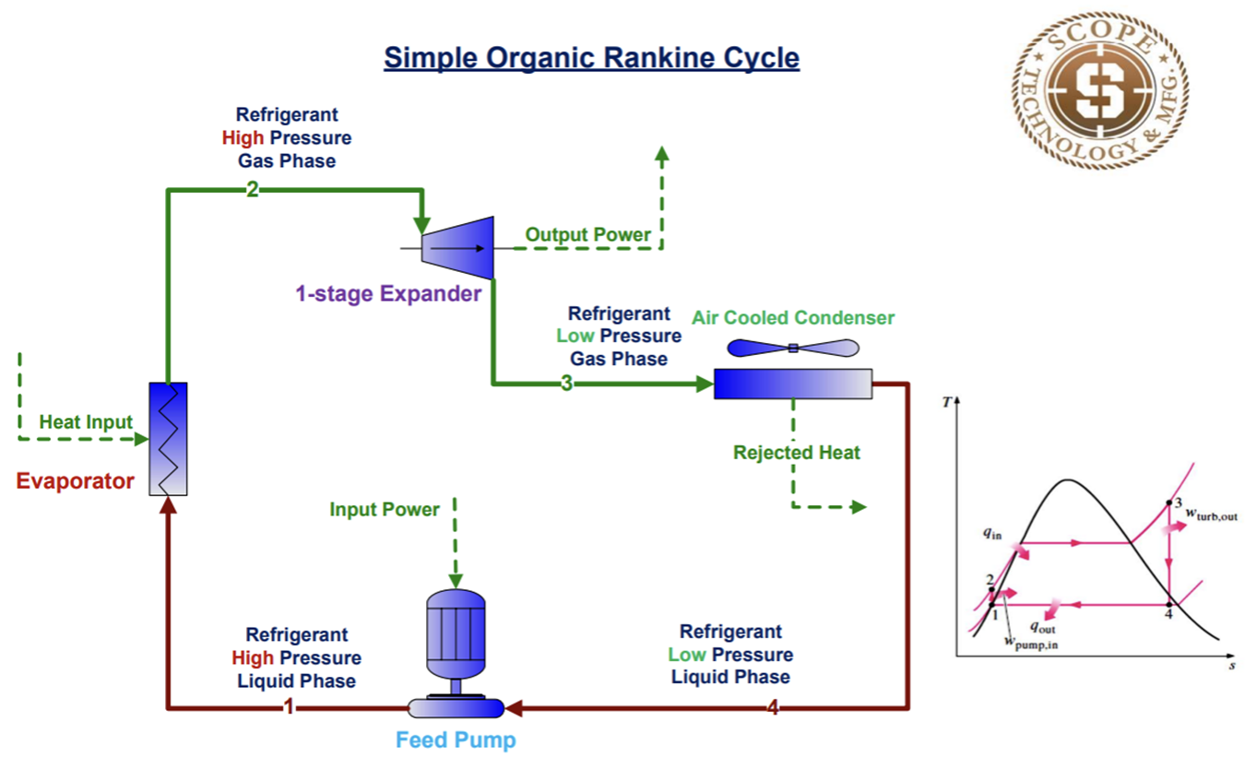

Before we dive into the effects of ambient temperatures, it is crucial to comprehend the fundamental principles of the O.R.C. cooling cycle. The O.R.C. system utilizes a closed-loop cycle, where a working fluid is pumped through a series of components, including an evaporator, expander, condenser, and pump. The working fluid absorbs heat from the waste heat source in the evaporator, expands through the expander, and then releases heat to the ambient environment in the condenser.

Impact of Ambient Temperatures on O.R.C. Efficiency

Ambient temperatures have a significant influence on the O.R.C. cooling cycle, affecting the system’s efficiency and performance. The primary impacts of ambient temperatures can be categorized into two main areas: heat rejection and working fluid properties.

Heat Rejection

Ambient temperatures directly impact the heat rejection process in the condenser. Higher ambient temperatures reduce the heat rejection capacity of the condenser, leading to:

- Increased condenser pressure: Elevated ambient temperatures increase the pressure in the condenser, which, in turn, increases the pumping power required to maintain the cycle. This results in higher energy consumption and lower overall efficiency.

- Reduced cooling capacity: The decreased heat rejection capacity of the condenser reduces the cooling capacity of the system, leading to lower output and efficiency.

On the other hand, lower ambient temperatures enhance the heat rejection process, resulting in:

- Improved condenser performance: Lower ambient temperatures reduce the pressure in the condenser, decreasing the pumping power required and increasing the overall efficiency of the system.

- Increased cooling capacity: The improved heat rejection capacity of the condenser increases the cooling capacity of the system, leading to higher output and efficiency.

Working Fluid Properties

Ambient temperatures also influence the properties of the working fluid, affecting its performance and efficiency. The most significant impacts include:

- Viscosity and density: Higher ambient temperatures increase the viscosity and density of the working fluid, reducing its flow rate and heat transfer capacity. This results in lower efficiency and output.

- Saturation temperature: The saturation temperature of the working fluid is directly affected by ambient temperatures. Higher ambient temperatures increase the saturation temperature, reducing the system’s efficiency and output.

Mitigating Negative Impacts and Amplifying Positive Ones

To minimize the negative impacts of ambient temperatures on O.R.C. efficiency and output, several strategies can be employed:

- Optimize system design: Careful design of the O.R.C. system, including the selection of working fluids and component sizing, can help mitigate the effects of ambient temperatures.

- Implement thermal management strategies: The use of thermal management strategies, such as heat shields, insulation, and cooling systems, can reduce the impact of ambient temperatures on the system.

- Select suitable working fluids: The selection of working fluids with favorable properties, such as low viscosity and high heat transfer capacity, can help minimize the effects of ambient temperatures.

- Utilize heat source selection: Selecting a suitable heat source, such as a high-temperature heat source, can reduce the impact of ambient temperatures on the system.

Conclusion

In conclusion, ambient temperatures have a profound impact on the efficiency and performance of O.R.C. systems. Understanding the effects of ambient temperatures on the cooling cycle and working fluid properties is crucial for optimizing system design and performance. By implementing strategies to mitigate the negative impacts and amplifying the positive ones, engineers and technical professionals can maximize the efficiency and output of O.R.C. units, leading to improved power generation and waste heat recovery in various applications.

Linking to Related and Future Topics

As we explore the intricacies of O.R.C. systems, it is essential to acknowledge the interconnectedness of topics within the study plan. The impact of temperature differentials on O.R.C. efficiency, heat source selection, and thermal management strategies are all critical components of optimizing O.R.C. performance. In the next article, we will delve into the Impact of Temperature Differentials on O.R.C. Efficiency, examining the effects of temperature differentials on system performance and exploring strategies for minimizing these impacts.